Digital twin technology is a rapidly growing part of the constantly evolving tech landscape. While some companies are not embracing what they see as akin to science fiction, digital twin technology is not a passing trend or a wave of the future.

While the concept is not new, the applications and use of digital twin technology are exponentially growing. 71% growth for standalone Digital Twin software from 2020-2022 is proof of that. Why? Simply due to the proven benefits Digital Twin Solutions provide, including improved productivity, safety and substantially reduced operational risk and costs.

Those unacquainted with this tech would do well to familiarise themselves with Digital Twin technology and its benefits.

What is Digital Twin Technology?

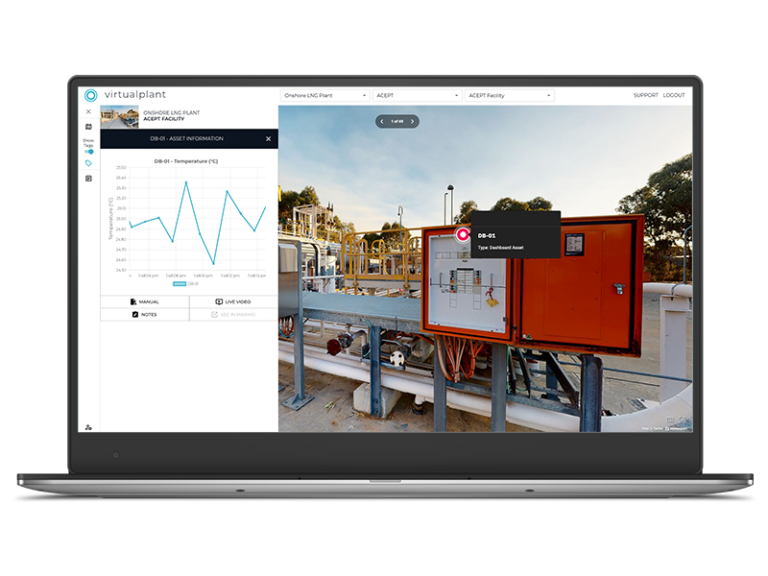

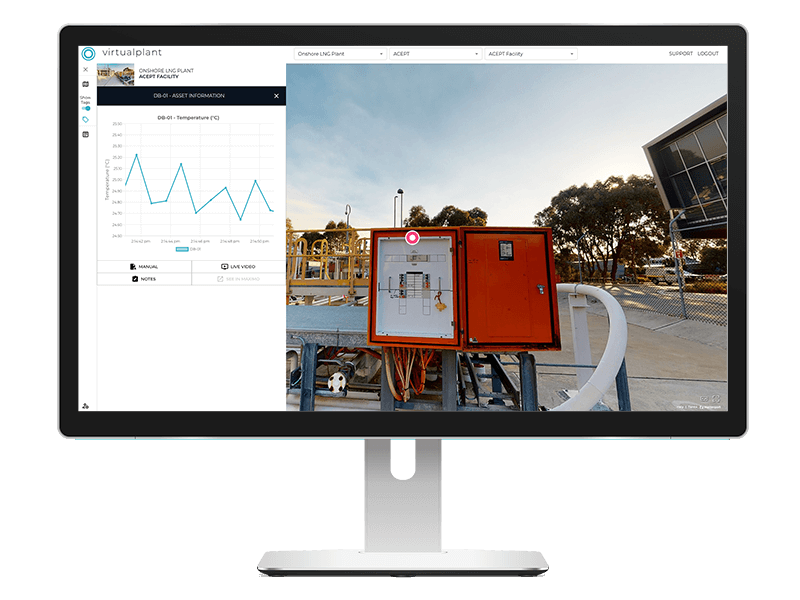

Digital Twin technology creates a virtual model of a physical object, system, or process. As a digital counterpart for the actual object, digital twins provide the opportunity to understand and predict outcomes, have real-time data for decision-making, optimising products, and enhancing connectivity. Additionally, Digital Twins are valuable across scores of industries with numerous applications.

Benefits of Digital Twins

It is difficult to overstate how many benefits Digital Twins offer to various industries. A significant benefit to those who use this technology is an overall improved product quality. There are many more benefits this technology provides. Here are several,

- Real-time monitoring

- Increased collaboration with efficient decision-making

- Reduced time to market and implementation

- Optimised performance

- Cost savings

- Increased customer satisfaction

History of Digital Twin Technology

Digital Twin technology has its roots in NASA. In the 1970s, the organisation began creating digital replicas to improve the physical simulation spacecraft models. While the name Digital Twin was not used until decades later, the idea of a twin in the digital realm opened doors to enhanced safety, security, and a vast number of other benefits that came from the technology. In 2002, Digital Twin technology made great strides in product lifecycle management. Since then, the tech has opened up possibilities in nearly every industry.

What Primary Problems is Digital Twin Technology Built to Solve

Predicting outcomes and spotting problems before they occur are two universally valuable applications for the tech. Digital Twins enables a vast number of industries to predict asset behaviour, analyse the lifespan of assets, find ways to improve maintenance, make decisions in real-time, along with numerous other benefits.

How Does Digital Twin Technology Work

Digital Twin Technology works by creating a virtual model of a physical object or system and using real-time data to simulate its behaviour and monitor operations.

Designing Digital Twins

Digital twins are usually 3D rendered models or set of drawings of physical objects, systems, or processes that accurately reflects their real-world counterparts. This can be done by importing conceptual models or scanning physical entities in the real world to visualise and analyse them in combination with enterprise and Internet of Things (IoT) data.

The Digital Twin concept consists of three distinct parts:

- The physical object or process and its physical environment

- The digital representation of the object or process, and

- The communication channel between the physical and virtual representations.

This model can be used to run simulations, integrations, testing and monitoring and maintenance work for its real world counterpart.

Creating Digital Twins

There are roughly six steps involved in creating and using Digital Twin technology.

- Data Collection- To make a virtual model, digital twins need information to understand an object or system’s behaviours or states in the real world.

- Virtual Representation- The data that was gathered instructs the user about the physical object’s functionality, features, and behaviour.

- Simulation- Once a virtual representation exists, it is used to allow interaction, visualisation, and analysis with the virtual model.

- Monitoring- The IoT data from the actual physical object monitors the virtual object’s operations and behaviour. This allows for decisions in real time as well as maintenance and optimisation.

- Collaboration- Because the digital twins allow a better understanding of the physical system or object, interdisciplinary teams can work together to build, test, deploy, operate, and best maintain complex systems interactively.

- Applications- The technology has applications across nearly every imaginable sector. As digital twin technology continues to evolve, the sky is the limit for potential uses.

Types of Digital Twins

There are a number of types of Digital Twins that are immensely useful either individually or in combination, depending on what the industry or company needs at any given time.

- Component Twins- These create replicas of individual pieces of a more extensive system. The digital twins help to optimise machinery, engine parts, or sensors.

- Asset Twins- These are replicas of entire physical facilities. They are used for optimisation, maintenance, or monitoring the asset’s performance.

- System Twins- Industries use system twins to simulate the interactions of multiple components or assets within a more extensive system. They optimise performance and can foresee problems.

- Process Twins- These twins are helpful in modelling and simulating complex processes. The twins represent the steps, inputs, outputs, and interactions in a specific area or with a particular machine.

Applications of Digital Twin Technology

While the applications of digital twin technology are practically endless, a recent IoT survey of 100 digital twin case studies found six main digital twin applications today:

- System Prediction- The technology can use known variables to predict complex outcomes.

- System Simulation- This shows the behaviour that can be expected

- Asset Interoperability- The tech creates standardised ways to integrate new assets into a system

- System Maintenance- Perfecting and implementing maintenance protocols

- System Visualisation- Digital twin technology can enhance transparency throughout the entire operational life cycle of a system.

- Product Simulation- Used primarily in the development phase to predict the behaviour of products

Future of Digital Twin Technology

Although digital twin technology is far from a new concept, its true transformative power has not been fully realised. Researchers are actively discussing using artificial intelligence and machine learning to increase digital twins’ capabilities further.

It has provided success when used in the space industry, construction, manufacturing, healthcare, supply chain, oil and gas, mining, urban planning, and similar industries. However, there are many more disciplines where digital twin technology could make excellent strides to shape the future.

The supporting technology necessary for digital twin implementation is in place and being used. These enablers include advanced algorithms, the ability to integrate external data, highly scalable computing power, availability of historical data, adaptable storage, and the technologies to make sense of it.

Expect more industries to move quickly and leverage the power of digital twin technology. Digital Twins cansense disruptions well before they occur and simulate a number of what-if situations, the impact of this technology will reach farther than many imagined.

Digital twin technology will continue to unify various platforms and deliver game-changing effects evident in a company’s bottom line. Additionally, digital twins will unite with other forms of technology, such as extended reality (XR), augmented reality (AR), and virtual reality (VR), to fashion an impressive immersive experience.