As the world demands more resources and less environmental impact from their extraction, mining companies are saddled with a difficult task.

That task is, extract more resources using less time and money while not endangering human life or the environment while still being held accountable for failure to meet expectations from shareholders, government, and the communities in which they operate.

With scrutiny of end-of-life asset environmental Impact on the rise so too is the need for sample collection.

Our client had a unique requirement to collect water samples from an inaccessible non-operational pit located in Western Australia’s Pilbara region.

These samples were necessary to identify pH, density, salinity, and metals/contaminants within the water that had gathered within the bottom of the pit. Due to the complex hydrology of the area and the stratification that occurs within a deep body of water, the samples needed to be gathered at a precise depth and location. This unique set of requirements meant RemSense needed to devise a set of procedures and Design / implement equipment capable of the safe recovery of samples and telemetry data gathered using an unmanned aerial vehicle (drone).

Traditional water sampling projects in remote locations are inherently complex and often impossible to reach due to the methods used in the decommissioning process. They are time-consuming, require watercraft or other vehicles, and come with substantial costs and often pose safety risks for the workers tasked with recovering samples.

This particular project’s complexity was increased by the challenging environment and terrain, the Unmanned aircraft needed to recover samples from locations up to 500 meters away and as deep as 200 meters below the pilot’s position at the closest access point.

During the project planning phase RemSense identified risks involving tether snagging, loss of radio control and scenarios where the aircraft becomes overweight. In addition to this the accurate measurement of water depth further added to the challenge of achieving the project’s goals.

RemSense rose to the challenge by developing two innovative devices that improved the performance and safety of the DJI M300 drone when being used for sample collection.

Load-Sensing aircraft tether hard point

Allows the pilot to be notified when a sensor payload reaches the bottom of a body of water and requires recovery, this reduces the risk of the tether coiling up on the bottom of the body of water being sampled and becoming snagged on debris.

Active payload safety release

The pilot is able to disconnect the recovered samples in the event of an emergency event eg snagging, overweight or powertrain malfunction, this device alone reduced the risk of the project significantly.

Tether (more than just a piece of string)

The tethering system created by RemSense allowed accurate at-depth sample recovery, rapid disconnection by ground crews and provides visual cues to the pilot that aid in the safe recovery of sample material.

Specialised flying techniques and procedures used by RemSense Pilots

RemSense’s pilots developed a series of procedures and techniques for flying safely while carrying suspended loads, safe sample recovery with site personnel and emergency procedures.

These were developed during hours of mock sample collection before the project even commenced.

RemSense’s industry leading solution led from an often difficult, dangerous or impossible task to getting consistent, reliable and replicable data collection allowing the client to make sound decisions when managing their asset.

In this instance, the project successfully collected hundreds of water samples from 11 different pits at multiple depths and locations within two weeks.

This achievement not only eliminated operational risks and potential contaminations but also resulted in significant time and cost savings for the client.

The team at RemSense designed a simple but effective UAV water sampling set up which allowed us to safely collect water samples from pit lakes at one of our Pilbarra sites.

They took the time to develop and test the sampling approach so we had confidence that we had everything we needed in place prior to mobilising to this remote site.

Adrian, Simon and the team were great to work with and we are busy planning the next round of sampling with them.

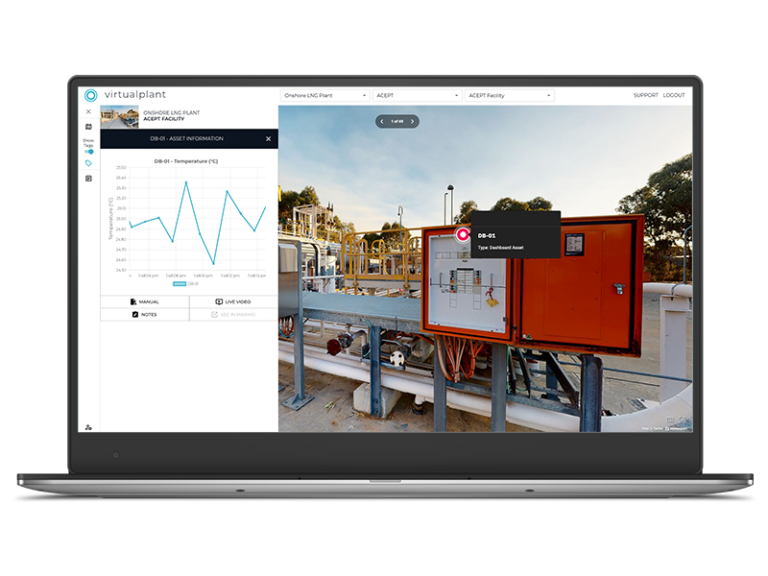

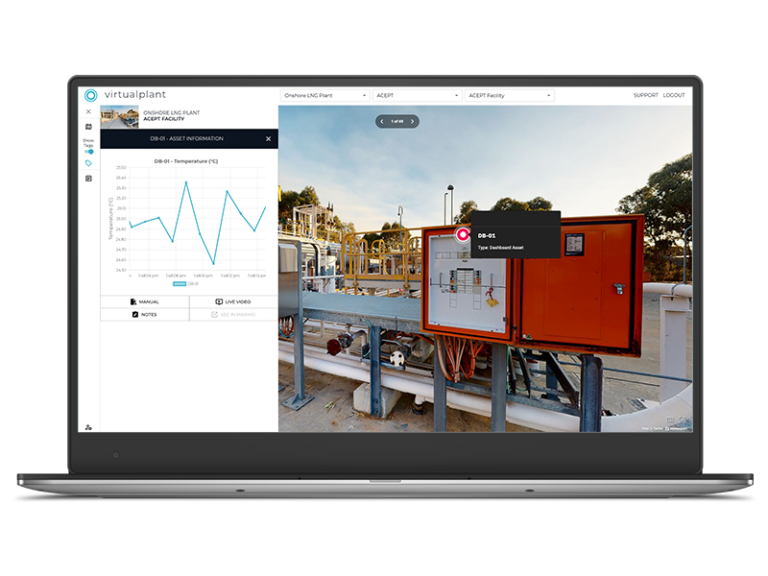

The future of Asset Management is just one click away

The future of Asset Management is just one click away

This website uses cookies to ensure you get the best experience on our site. To find out more read our privacy policy.